What the King’s Award Means to Us at Mixergy

We are thrilled to have received a King’s Enterprise Award for Innovation. This recognition is a fantastic tribute to the hard work and dedication across our business which has enabled the launch of our flagship product—the integrated heat pump cylinder, otherwise known as iHP.

Developing the iHP meant taking a bold step to create a modularised heat pump that works in harmony with our intelligent hot water cylinder platform. This innovation allows us to deliver:

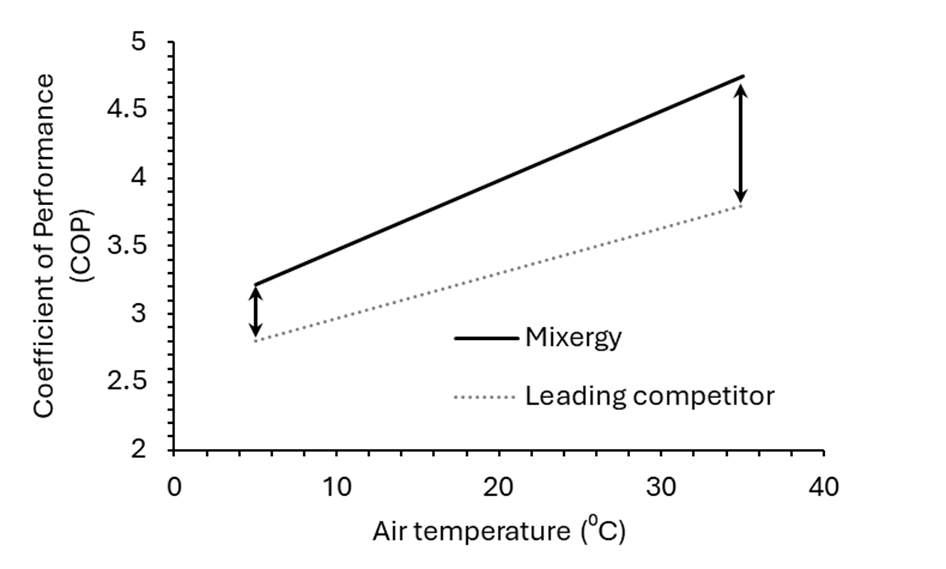

- The lowest operating cost – achieved by combining a high seasonal Coefficient of Performance (sCOP) with optimal integration across renewable time-of-use tariffs.

- The fastest reheat performance – made possible by exploiting thermal stratification, enabling the iHP to recover to a useful temperature far quicker than conventional systems.

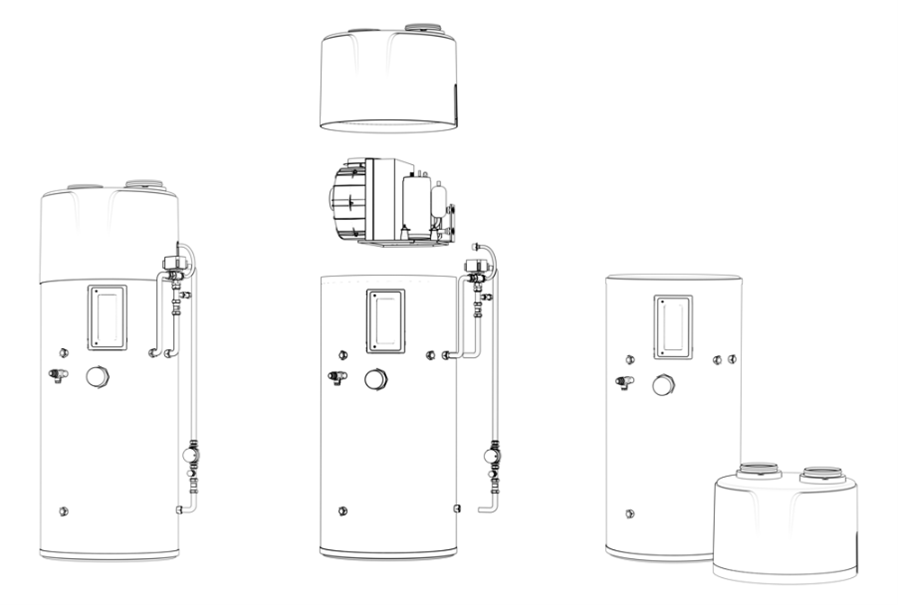

- The best lifecycle performance – with a modular design that is fully serviceable over the 25-year life of the cylinder, helping customers stay on the journey to net zero by 2050.

This article delves into the specifics of the iHP: how it benefits the grid, how it reduces running costs, and how additional developments have meant that iHP now optimises the use of both solar from the roof and wind from the grid!

1) What is iHP and Why Is It So Innovative?

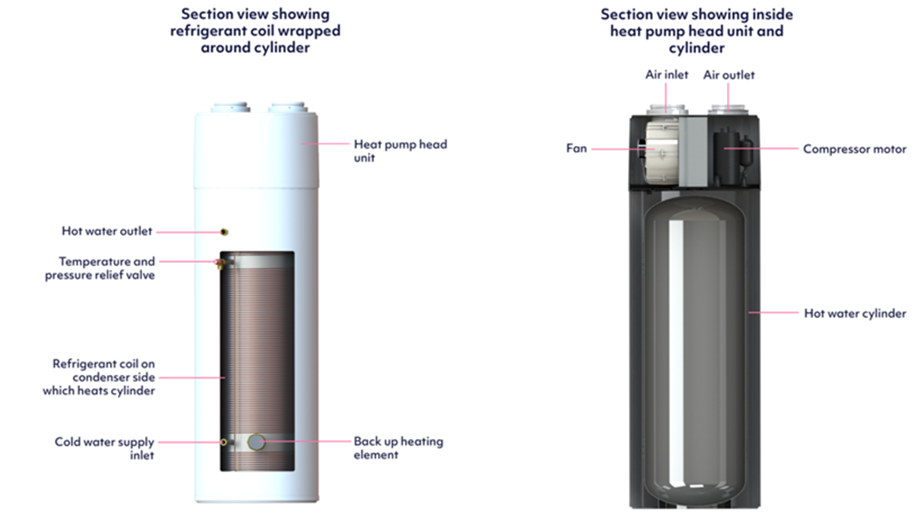

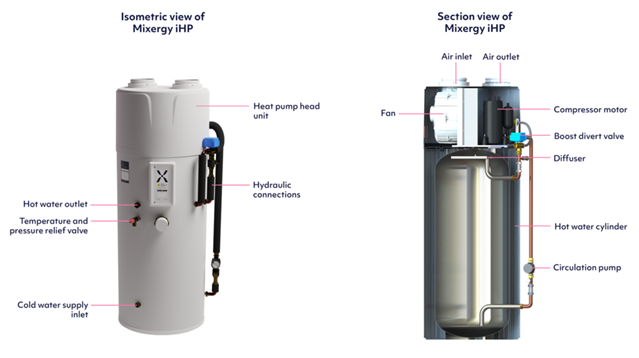

Mixergy’s iHP is a hot water cylinder with a small heat pump mounted on top. While this configuration isn’t new in itself, conventional systems have serious drawbacks. In a traditional setup, refrigerant lines are wrapped around the tank, this causes several key issues:

- All-or-nothing heating – Conventional systems heat the entire tank regardless of demand, which means they can take up to six hours to reach a usable temperature from cold.

- Reduced performance in partial charge – When re-heating from a partially depleted tank, the available heat transfer surface area is smaller, significantly reducing performance—up to 40% COP loss in real-world use.

- Environmental and serviceability concerns – As the industry moves away from high-GWP refrigerants like R134A (GWP ~1,400) towards low-GWP alternatives like R290 (propane, GWP ~3), design challenges arise. R290 is flammable, so refrigerant lines must be brazed, making the system non-serviceable. If the heat pump fails, the entire unit—including the tank— must be replaced. Manufacturers only offer a 5-year warranty on these systems as a result.

Mixergy’s iHP addresses these problems with a radically different approach:

- a) Modular, external heating – The iHP heats water in a separate, removable heat pump module, which then reinjects the water at a useful temperature into the top of the tank. This allows much faster heat-up times—up to 10x faster than conventional systems—without relying on inefficient electric immersion heaters.

- b) Optimised COP via thermal stratification – For the best efficiency, the iHP can reinject water into the bottom of the cylinder, maintaining a large temperature differential and maximising heat pump efficiency. Independent testing, demonstrated that iHP delivers a 15–25% COP improvement across air temperatures from 5°C to 35°C.

- c) Serviceable, long-life design – The modular heat pump can be removed and serviced without scrapping the cylinder, this extends the system life to match the 25 year lifetime of the stainless cylinder which means that iHPs installed today will still be running by the time we have (hopefully!) hit net zero in 2050.

But innovation doesn’t stop at the product level. Since launching the iHP, we’ve focused on how it interacts across the wider energy system, whether we’re talking local roof-top solar PV generation to national wind generation from the grid.

2) Why We Continue to Innovate Around the Grid and the Role of SSES

One of today’s major energy challenges is the waste from renewable curtailment—billions of pounds are spent each year in the UK to shut down surplus wind generation, see previous article. which delves into this topic a bit further.

The Mixergy iHP is connected to our intelligent software platform, which enables us to activate systems where surplus renewable power exists. This flexibility can be triggered by time-of-use tariffs or local grid frequency signals, meaning the iHP can help provide grid inertia—a role traditionally performed by large, high inertia plant such as coal, nuclear or hydro-electric power plants.

Recent blackouts in Portugal and Spain illustrate the risks of retiring fossil-based generators that provided mechanical inertia. Without them, we need new methods to ensure grid stability. These include batteries, smart EV chargers, Mixergy tanks, and now—the Mixergy iHP.

Creating this type of distributed grid flexibility requires robust infrastructure. That’s why the Smart and Secure Electricity System (SSES) consultation is so timely and important. It offers a pathway to pay householders—including those with iHPs in their cupboards—to absorb excess energy, instead of curtailing wind farms.

3) The Latest Step: iHP Integration with Local Solar PV

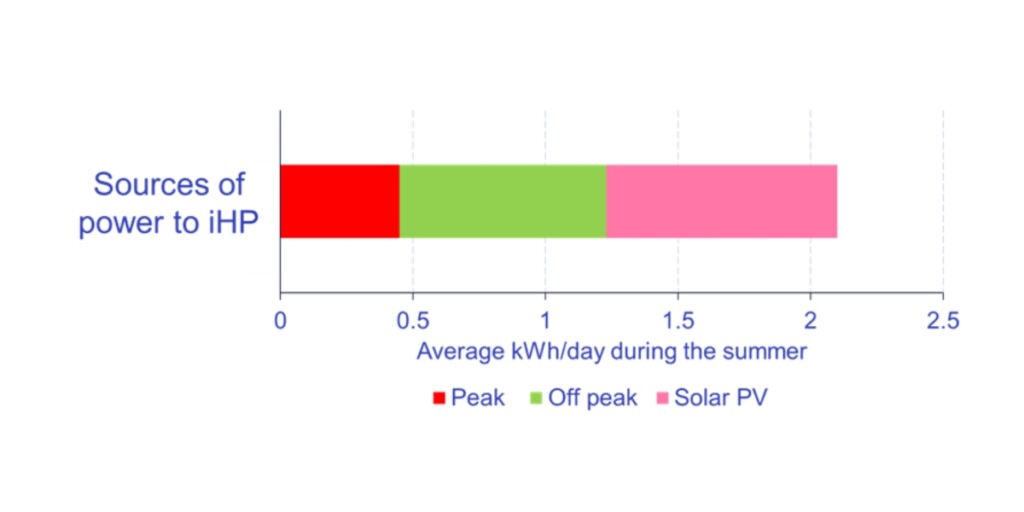

Mixergy’s iHP now integrates with solar PV and home energy monitoring. This allows our platform to:

- Track whole-house consumption

- Combine this data with weather forecasts, solar export data, and tariff prices

- Deliver lowest-cost operation under varying conditions

This means an iHP installed today is future-proofed—whether responding to national price signals or optimising local solar use. Examples include:

- Creating more headroom for solar by charging a little less from the grid at night to make use of solar that is forecast the following day

- Shifting heating schedules on winter days to balance the cost of electricity vs. heat pump efficiency (e.g. cheaper electricity in the morning vs. higher sCOP in the afternoon).

- Using negative pricing events, where surplus wind (e.g. from Scotland) or solar (e.g. from the South West) can be absorbed cheaply.

By combining smart tariff use with intelligent solar integration, we can dramatically reduce the running cost of a heat pump cylinder.

In summary, the innovations across iHP deliver:

- Up to 25% efficiency gains from improved COP at the product level

- A further 30%+ cost reduction through smart control within the wider energy system

4) Closing Thoughts

If you’ve made it this far, we hope it’s clear just how many layers of innovation and system thinking have gone into Mixergy’s iHP. From faster heat-up times to smarter grid interactions and solar optimisation, this is a new kind of hot water system—designed for today and the net-zero future out to 2050 and beyond.

We are incredibly proud that the King’s Award for Enterprise has recognised our work on the iHP. A huge thank you to the Mixergy team, who have worked tirelessly to bring this vision to life. The launch of iHP compliments recent announcements from government to mandate the installation of solar on new build roofs as part of the emerging Future Home Standard.

Receiving this award just as our first large iHP consignments head to new build and social housing retrofit projects is perfect timing—and a huge boost for our mission.

Pete Armstrong, Mixergy CEO and Co-Founder